Home /

Expert Answers /

Other /

1-2-3-4-5-appendix-a-the-auckland-motors-case-study-auckland-motors-ltd-opened-its-motor-spare-parts

(Solved): 1 2 3 4 5 Appendix A - The Auckland Motors Case Study Auckland Motors Ltd opened its motor spare pa ...

1 2 3 4 5 Appendix A - The Auckland Motors Case Study Auckland Motors Ltd opened its motor spare parts shop in Henderson, West Auckland in 1995. Since then it has two more shops in Auckland, one in Albany and the other in Westgate. The company now requires computerising its business processes. Due to an increase in their business activity, the manual processing of sales orders now impacts their ability to serve their customers on time. Due to work pressure their staff members are making far too many errors in processing sales orders. The company owner knows that computerisation is now needed and requests that a Sales Order Processing System (a Transaction Processing System) to be developed and implemented in their three shops. The following is a brief description of their manual Sales Order Processing System compiled based on interviews conducted with the owner of Auckland Motors Ltd. 6 7 00 9 10 11 12 13 14 15 Auckland Motors Ltd mostly sells spare parts of Japanese made vehicles of all models such as that of Toyota, Mazda, Nissan, and Honda etc. Sales orders for spare parts are received from customers. They keep record of all their customers on a customer folder. The order is validated to ensure that the parts ordered by their customer are appropriate Japanese vehicle parts. Descriptions of all the vehicle parts are kept on a folder, identifying each part to a particular type of Japanese vehicle, its model and the year in which the vehicle was made. Any invalid order is sent back to the customer. 16 17 18 19 20 21 22 23 24 25 If it is a valid order, then a check is done to determine if the parts ordered by the customer are in stock. Auckland Motors keep an up-to-date record of stock levels of each part on stock cards. If all the parts ordered are in stock then the customer order is placed in the fill-order folder to be processed. For a customer order which they can only partially fill, because some of the parts ordered are not in their stock, the order is split into two orders; one order will have the parts that are in stock, which is filed in the fill-order folder. The other order will have all the ordered parts by the customer not currently in the stock. This order is placed in the unfilled-order folder. If a valid order can't be filled, since parts ordered are all out of stock, then the order is also filed in the unfilled-order folder. When a fill-order file is processed, the stock folder is updated and an invoice is produced. To produce an invoice, the customer details are obtained from the customer folder. The selling price of vehicle parts are kept on the selling price folder, while any vehicle part offered on a 26 27 28 29 30 31 32 discounted rate is kept on a discount-rates folder. The selling price and discount rate is used 33 34 35 36 37 to determine the price that they would be charged for a part, which is multiplied by the quantity ordered to give a total cost. Finally, all the individual total costs for the ordered parts are added to produce a balance (owing) for an invoice. Any previous outstanding balance of a customer must be brought forward and included in the current invoice. At Auckland Motors Ltd, the outstanding customer balance is kept on a customer-outstanding folder which is also updated with the current balance when an invoice is produced. Here, the customer- transactions folder has details of all their customer transactions which are updated when an invoice is produced. Auckland Motors Ltd dispatches the ordered parts with an invoice to their customer. A copy of customer invoice is sent to the accounts clerk (Auckland Motors Ltd). 38 39 40 41 42 43 44 45 The back order process deals with the unfilled-order folder. The unfilled-order folder has customer orders which can't be filled since the parts ordered are all out of stock. At Auckland Motors Ltd, these orders at a later time must be filled. Based on these orders, the parts out of stock have to be immediately re-ordered from appropriate suppliers. Auckland Motors maintains a supplier information folder. Purchase orders are sent to the suppliers. 46 47 48 Read the case study carefully and answer the following questions. 1. List the external entities in the case study. You may find useful to list the line numbers where the external entities are found. 3 marks 2. Identify the inputs and outputs from the system. Relate these to the external entities you listed in part (a). List them in the space provided below. 5 marks Inputs From external Line Outputs To external Line entities no. entities no. List inputs List the external List the outputs List the external here entities here here entities here 4. Draw a top (high) level data flow diagram that illustrates all the processes, inputs, outputs and external entities of the Auckland motor case study. Remember to indicate those external entities and data storage that are repeated. 17 marks 3. Draw a context diagram that provides an overview of the Auckland motors case study, illustrating the system as a single process with its inputs, outputs and external entities, from your answer in part (b). 8 marks 5. Draw a second (low) level DFD of a process of your choice, which you have with the top (high) level DFD in part (d). Note: Only include data flows, processes, and external entities that are relevant to this process (process of your choice). 7 marks

Expert Answer

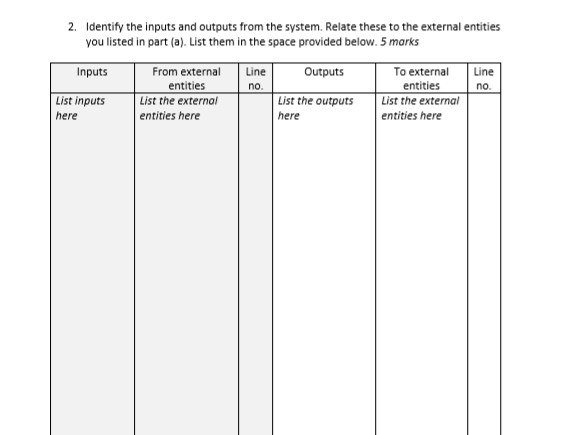

Answer to 1 2 3 4 5 Appendix A - The Auckland Motors Case Study Auckland Motors Ltd opened its motor spare parts shop in Henderson...