(Solved): 1 Problem 1: Electronics Assembly Line An electronics factory assembles circuit boards with the foll ...

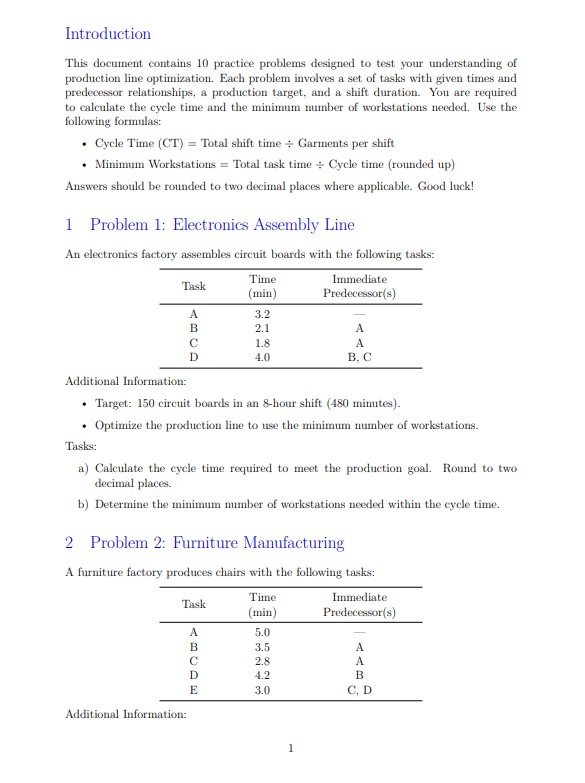

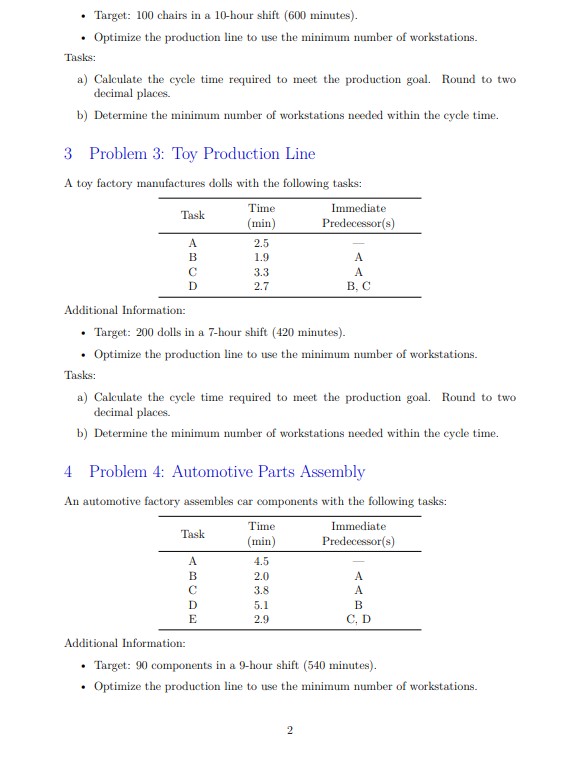

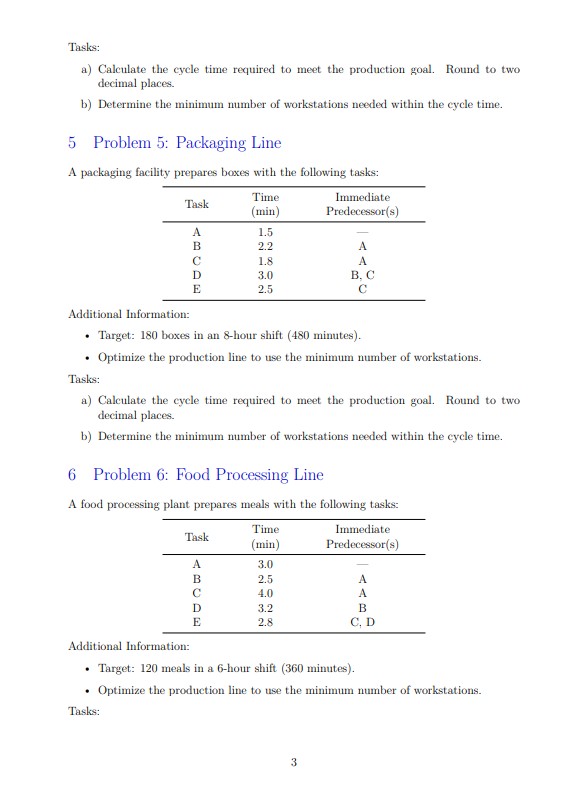

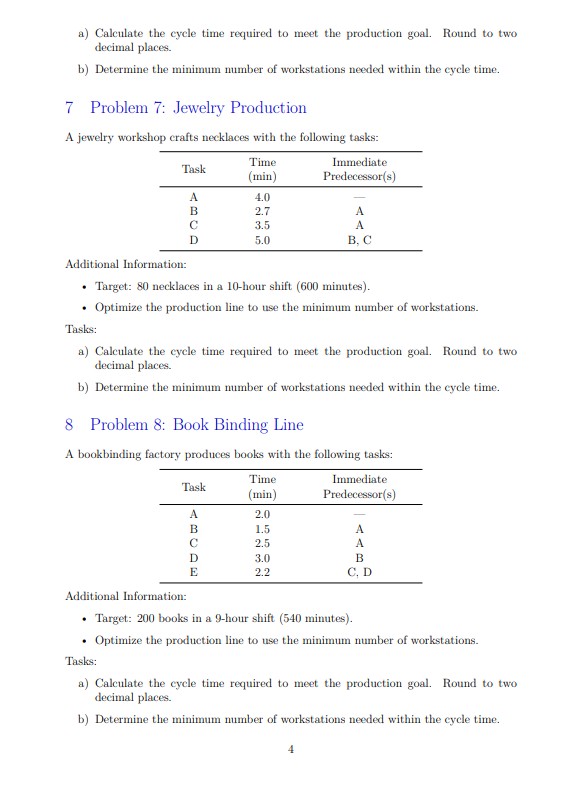

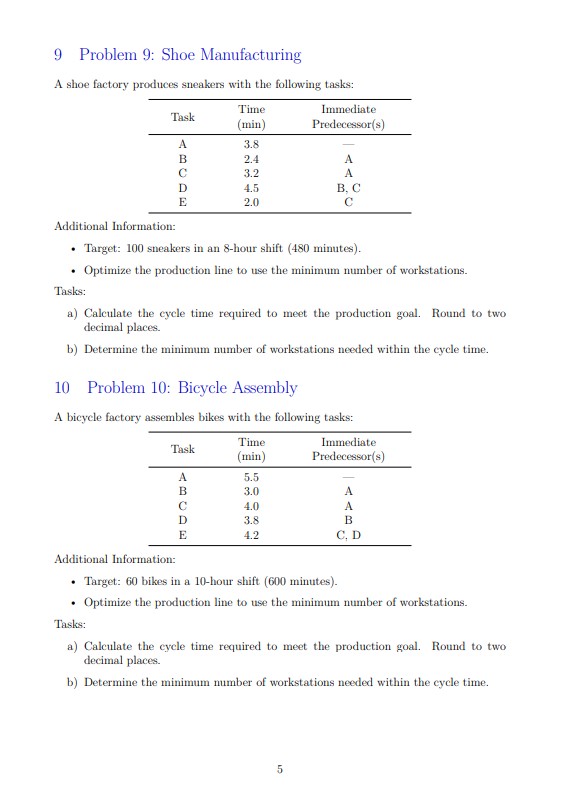

1 Problem 1: Electronics Assembly Line An electronics factory assembles circuit boards with the following tasks: Task Time (min) Immediate Predecessor(s) A 3.2 — B 2.1 A C 1.8 A D 4.0 B, C Additional Information: • Target: 150 circuit boards in an 8-hour shift (480 minutes). • Optimize the production line to use the minimum number of workstations. Tasks: a) Calculate the cycle time required to meet the production goal. Round to two decimal places. b) Determine the minimum number of workstations needed within the cycle time. 2 Problem 2: Furniture Manufacturing A furniture factory produces chairs with the following tasks: Task Time (min) Immediate Predecessor(s) A 5.0 — B 3.5 A C 2.8 A D 4.2 B E 3.0 C, D Additional Information: • Target: 100 chairs in a 10-hour shift (600 minutes). • Optimize the production line to use the minimum number of workstations. Tasks: a) Calculate the cycle time required to meet the production goal. Round to two decimal places. b) Determine the minimum number of workstations needed within the cycle time. 3 Problem 3: Toy Production Line A toy factory manufactures dolls with the following tasks: Task Time (min) Immediate Predecessor(s) A 2.5 — B 1.9 A C 3.3 A D 2.7 B, C Additional Information: • Target: 200 dolls in a 7-hour shift (420 minutes). • Optimize the production line to use the minimum number of workstations. Tasks: a) Calculate the cycle time required to meet the production goal. Round to two decimal places. b) Determine the minimum number of workstations needed within the cycle time. 4 Problem 4: Automotive Parts Assembly An automotive factory assembles car components with the following tasks: Task Time (min) Immediate Predecessor(s) A 4.5 — B 2.0 A C 3.8 A D 5.1 B E 2.9 C, D Additional Information: • Target: 90 components in a 9-hour shift (540 minutes). • Optimize the production line to use the minimum number of workstations. Tasks: a) Calculate the cycle time required to meet the production goal. Round to two decimal places. b) Determine the minimum number of workstations needed within the cycle time. 5 Problem 5: Packaging Line A packaging facility prepares boxes with the following tasks: Task Time (min) Immediate Predecessor(s) A 1.5 — B 2.2 A C 1.8 A D 3.0 B, C E 2.5 C Additional Information: • Target: 180 boxes in an 8-hour shift (480 minutes). • Optimize the production line to use the minimum number of workstations. Tasks: a) Calculate the cycle time required to meet the production goal. Round to two decimal places. b) Determine the minimum number of workstations needed within the cycle time. 6 Problem 6: Food Processing Line A food processing plant prepares meals with the following tasks: Task Time (min) Immediate Predecessor(s) A 3.0 — B 2.5 A C 4.0 A D 3.2 B E 2.8 C, D Additional Information: • Target: 120 meals in a 6-hour shift (360 minutes). • Optimize the production line to use the minimum number of workstations. Tasks:1 a) Calculate the cycle time required to meet the production goal. Round to1