Home /

Expert Answers /

Mechanical Engineering /

4-gland-nut-1-reqd-brs-1-valve-body-1-reoo-brs-5-cap-1-reqd-brs-all-fillets-and-pa575

(Solved): (4) GLAND NUT (1 REQD - BRS) (1) Valve Body (1) REOO - BRS! (5) CAP (1 REQD - BRS) ALL FILLETS AND ...

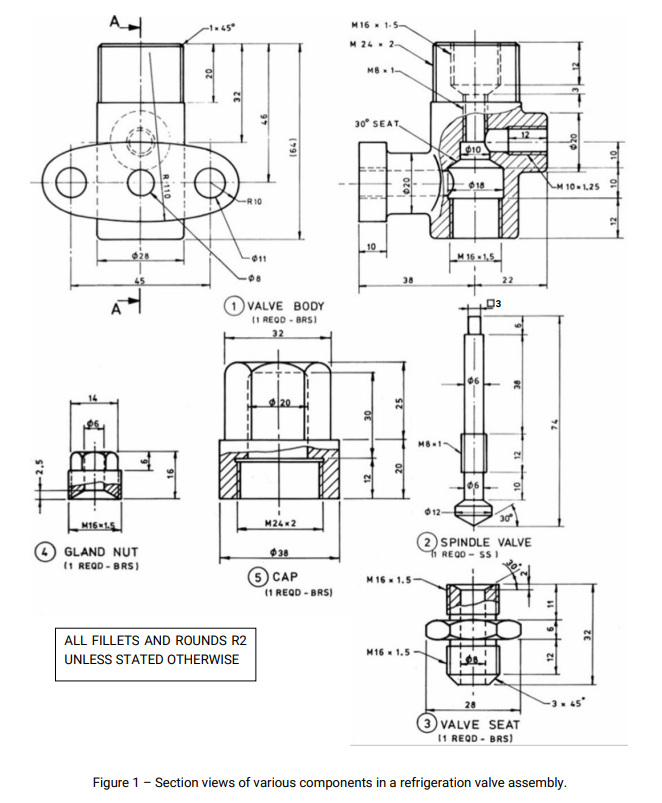

(4) GLAND NUT (1 REQD - BRS) (1) Valve Body (1) REOO - BRS! (5) CAP (1 REQD - BRS) ALL FILLETS AND ROUNDS R2 UNLESS STATED OTHERWISE (2) SPINDLE VALVE 2. REOD - SS I (3) VALVE SEAT (1 REQD - BRS) Figure 1 - Section views of various components in a refrigeration valve assembly.

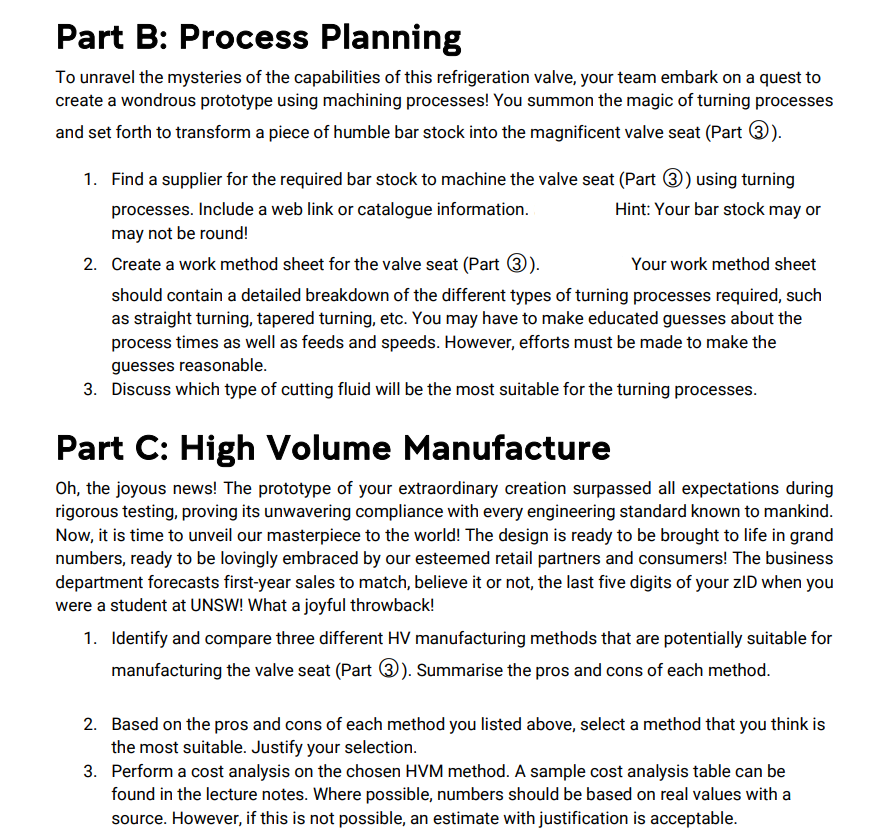

Part B: Process Planning To unravel the mysteries of the capabilities of this refrigeration valve, your team embark on a quest to create a wondrous prototype using machining processes! You summon the magic of turning processes and set forth to transform a piece of humble bar stock into the magnificent valve seat (Part (3)). 1. Find a supplier for the required bar stock to machine the valve seat (Part (3)) using turning processes. Include a web link or catalogue information. Hint: Your bar stock may or may not be round! 2. Create a work method sheet for the valve seat (Part (3)). Your work method sheet should contain a detailed breakdown of the different types of turning processes required, such as straight turning, tapered turning, etc. You may have to make educated guesses about the process times as well as feeds and speeds. However, efforts must be made to make the guesses reasonable. 3. Discuss which type of cutting fluid will be the most suitable for the turning processes. Part C: High Volume Manufacture Oh, the joyous news! The prototype of your extraordinary creation surpassed all expectations during rigorous testing, proving its unwavering compliance with every engineering standard known to mankind. Now, it is time to unveil our masterpiece to the world! The design is ready to be brought to life in grand numbers, ready to be lovingly embraced by our esteemed retail partners and consumers! The business department forecasts first-year sales to match, believe it or not, the last five digits of your zID when you were a student at UNSW! What a joyful throwback! 1. Identify and compare three different HV manufacturing methods that are potentially suitable for manufacturing the valve seat (Part (3). Summarise the pros and cons of each method. 2. Based on the pros and cons of each method you listed above, select a method that you think is the most suitable. Justify your selection. 3. Perform a cost analysis on the chosen HVM method. A sample cost analysis table can be found in the lecture notes. Where possible, numbers should be based on real values with a source. However, if this is not possible, an estimate with justification is acceptable.