Home /

Expert Answers /

Civil Engineering /

a-hot-mix-asphalt-surface-course-50-mm-thick-is-to-be-designed-to-carry-15-000-000-esals-during-th-pa934

(Solved): A hot mix asphalt surface course (50 mm thick) is to be designed to carry 15,000,000 ESALS during th ...

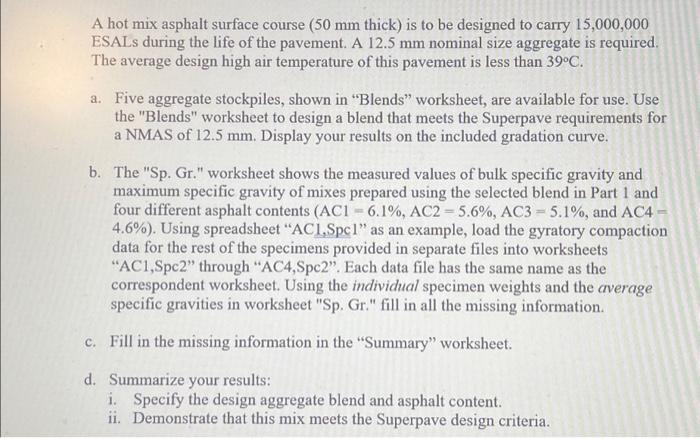

A hot mix asphalt surface course (50 mm thick) is to be designed to carry 15,000,000 ESALS during the life of the pavement. A 12.5 mm nominal size aggregate is required. The average design high air temperature of this pavement is less than 39°C. a. Five aggregate stockpiles, shown in "Blends" worksheet, are available for use. Use the "Blends" worksheet to design a blend that meets the Superpave requirements for a NMAS of 12.5 mm. Display your results on the included gradation curve. b. The "Sp. Gr." worksheet shows the measured values of bulk specific gravity and maximum specific gravity of mixes prepared using the selected blend in Part 1 and four different asphalt contents (AC1 = 6.1%, AC2 = 5.6%, AC3= 5.1%, and AC4 = 4.6%). Using spreadsheet "AC1,Spc1" as an example, load the gyratory compaction data for the rest of the specimens provided in separate files into worksheets "AC1,Spc2" through "AC4,Spc2". Each data file has the same name as the correspondent worksheet. Using the individual specimen weights and the average specific gravities in worksheet "Sp. Gr." fill in all the missing information. c. Fill in the missing information in the "Summary" worksheet. d. Summarize your results: i. Specify the design aggregate blend and asphalt content. ii. Demonstrate that this mix meets the Superpave design criteria.

A hot mix asphalt surface course ( thick) is to be designed to carry ESALs during the life of the pavement. A nominal size aggregate is required. The average design high air temperature of this pavement is less than . a. Five aggregate stockpiles, shown in "Blends" worksheet, are available for use. Use the "Blends" worksheet to design a blend that meets the Superpave requirements for a NMAS of . Display your results on the included gradation curve. b. The "Sp. Gr." worksheet shows the measured values of bulk specific gravity and maximum specific gravity of mixes prepared using the selected blend in Part 1 and four different asphalt contents , and ). Using spreadsheet "ACl,Spcl" as an example, load the gyratory compaction data for the rest of the specimens provided in separate files into worksheets "AC1,Spc2" through "AC4,Spc2". Each data file has the same name as the correspondent worksheet. Using the individual specimen weights and the average specific gravities in worksheet "Sp. Gr." fill in all the missing information. c. Fill in the missing information in the "Summary" worksheet. d. Summarize your results: i. Specify the design aggregate blend and asphalt content. ii. Demonstrate that this mix meets the Superpave design criteria.