(Solved): Develop a material requirements plan for component H. Lead times for the end item and each component ...

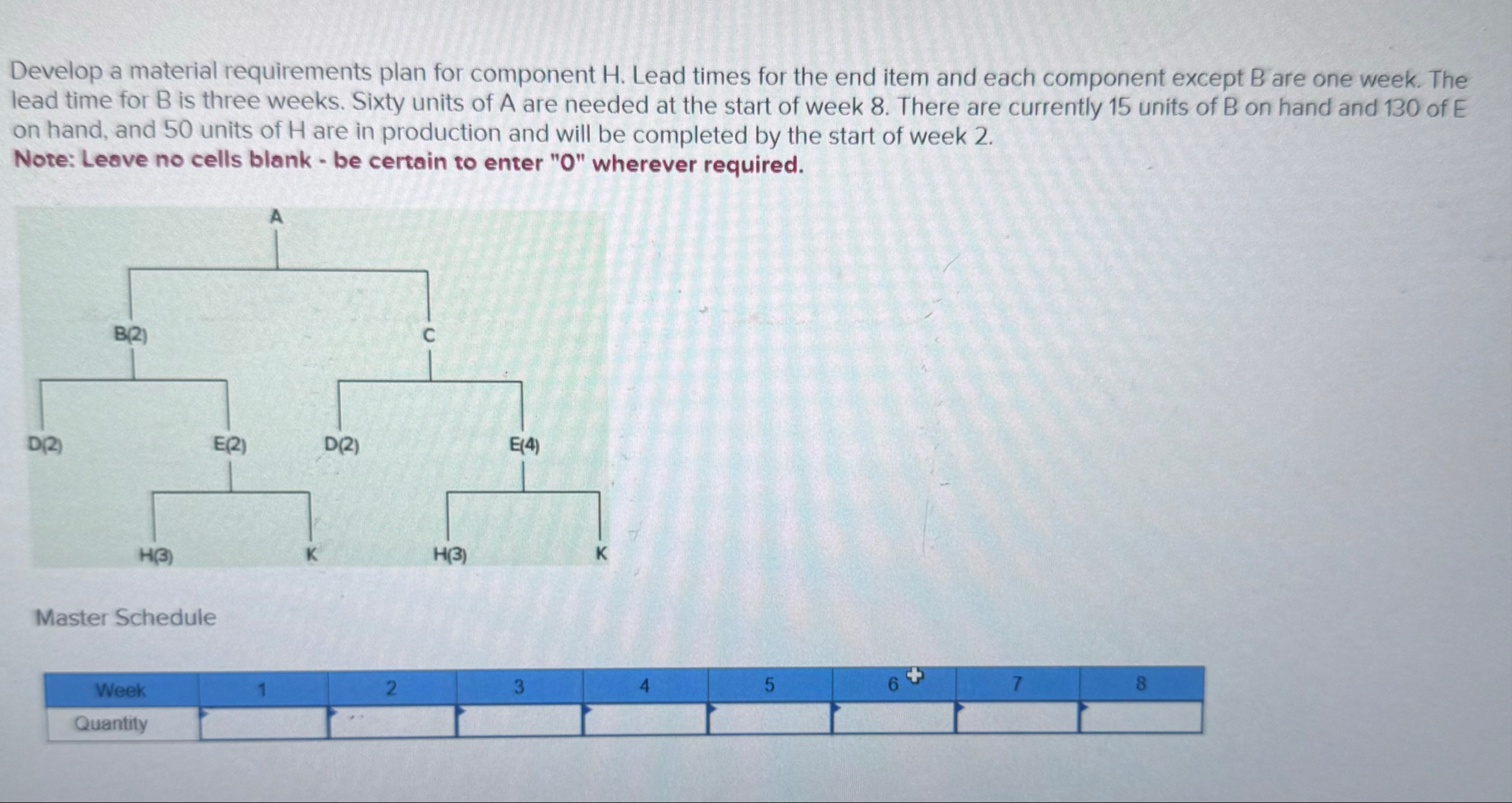

Develop a material requirements plan for component

H. Lead times for the end item and each component except

Bare one week. The lead time for B is three weeks. Sixty units of A are needed at the start of week 8. There are currently 15 units of B on hand and 130 of E on hand, and 50 units of H are in production and will be completed by the start of week 2 . Note: Leave no cells blank - be certain to enter " 0 " wherever required. Master Schedule \table[[Week,1,2,3,4,5,

6^(? ),7,8],[Quantity,,,,,,,,]]\table[[

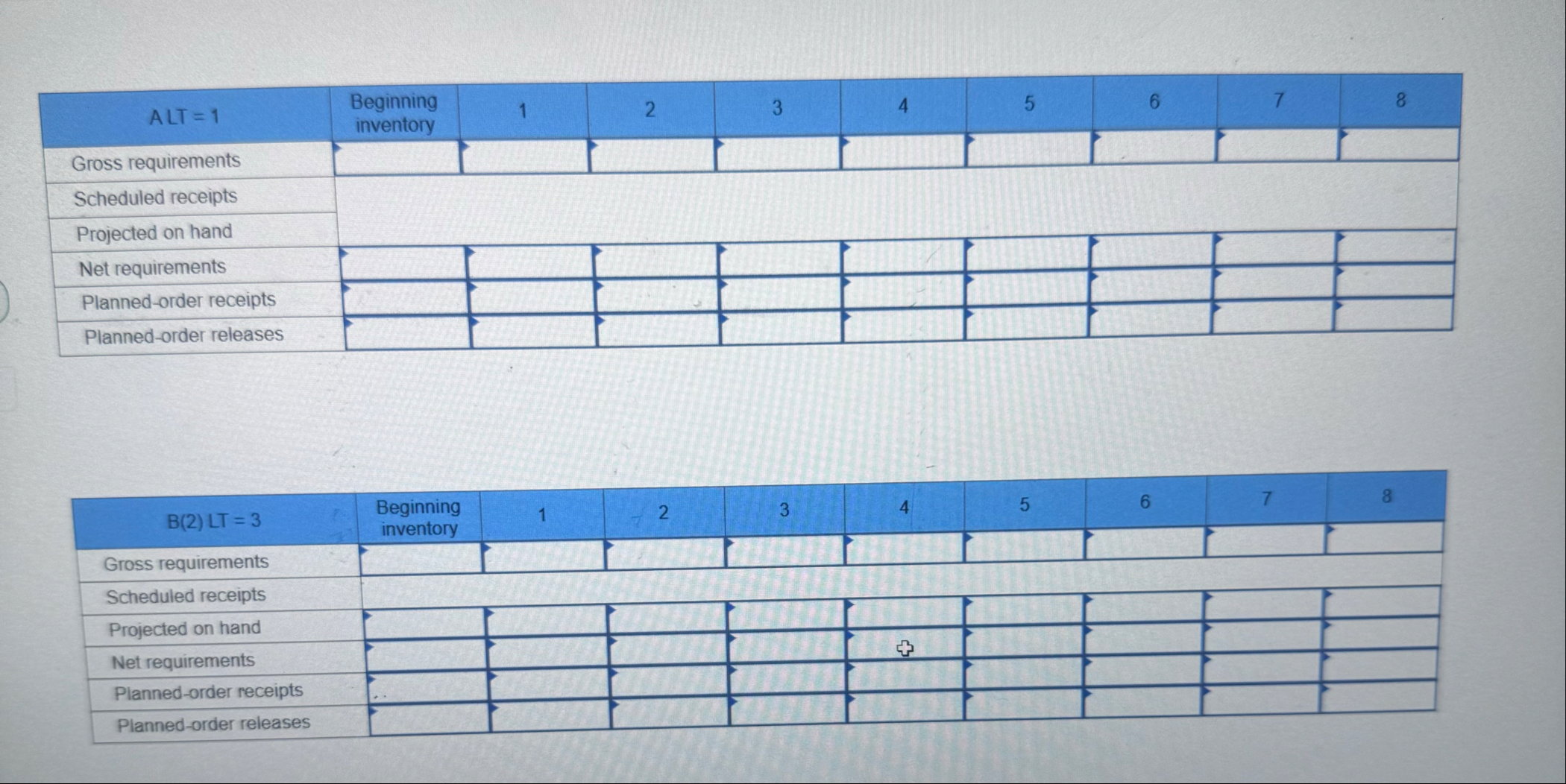

ALT=1,Beginning inventory,1,2,3,4,5,6,7,8],[Gross requirements,,,,,,,,,],[Scheduled receipts,],[Projected on hand],[Net requirements],[Planned-order receipts],[Planned-order releases]] \table[[

B(2)LT=3,Beginning inventory,1,2,3,4,5,6,7,8],[Gross requirements,,,,,,,,,],[Scheduled receipts,,,,,,,,,],[Projected on hand,,,,,,,,,],[Net requirements,,,,,,,,,],[Planned-order receipts,,,,,,,,,],[Planned-order releases,,,,,,,,,]]\table[[

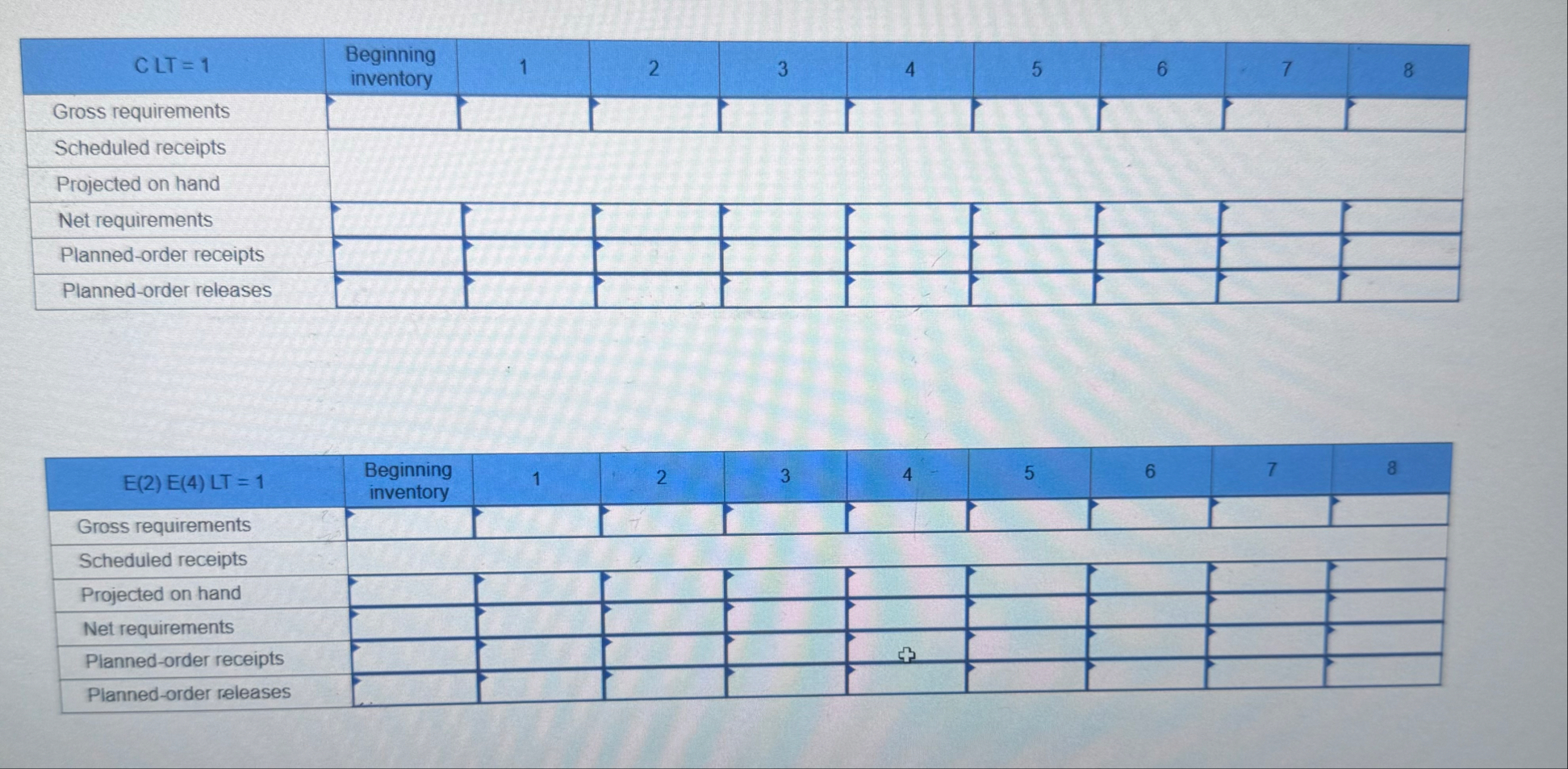

CLT=1,Beginning inventory,1,2,3,4,5,6,7,8],[Gross requirements,,,,,,,,,],[Scheduled receipts,],[Projected on hand],[Net requirements,,,,,,,,,],[Planned-order receipts,,,,,,,,,],[Planned-order releases,,,,,,,,,]] \table[[

E(2)E(4)LT=1,Beginning inventory,1,2,3,4,5,6,7,8],[Gross requirements,,,,,,,,,],[Scheduled receipts,],[Projected on hand,,,,,,,,,],[Net requirements,,,,,,,,,],[Planned-order receipts,,,,,,,,,],[Planned-order releases,,,,,,,,,]]\table[[H(E3)

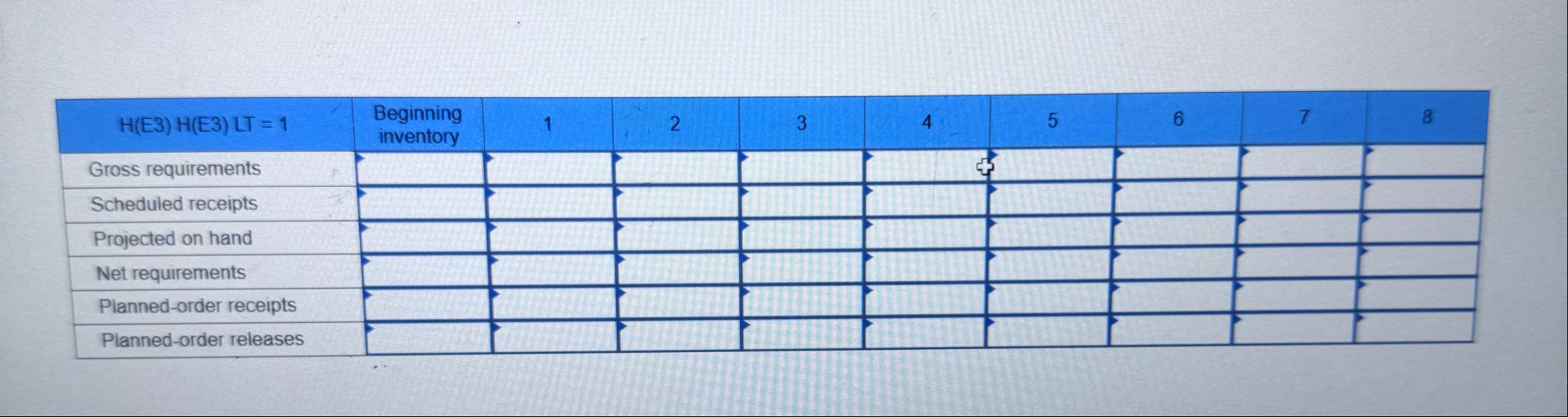

H(E3)LT=1,Beginning inventory,1,2,3,4,5,6,7,8],[Gross requirements,,,,,,,,,],[Scheduled receipts,,,,,,,,,],[Projected on hand,,,,,,,,,],[Net requirements,,,,,,,,,],[Planned-order receipts,,,,,,,,,],[Planned-order releases,,,,,,,,,]]