Home /

Expert Answers /

Operations Management /

please-help-nbsp-the-following-tasks-are-to-be-performed-on-an-assembly-line-see-image-attache-pa355

(Solved): PLEASE HELP:::: The following tasks are to be performed on an assembly line: *see image attache ...

PLEASE HELP::::

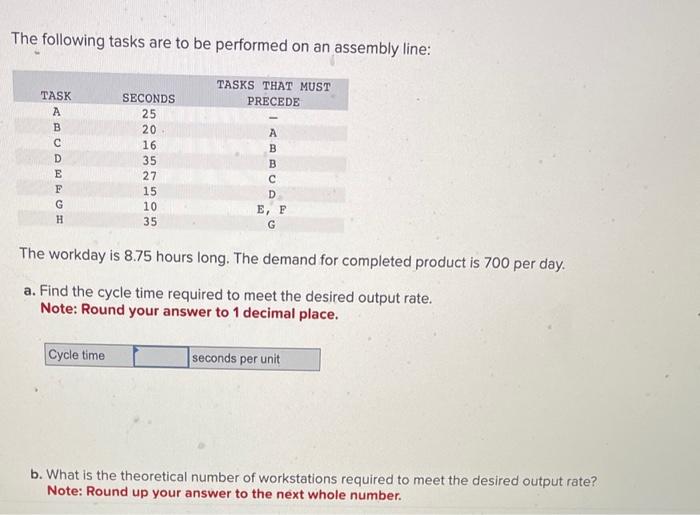

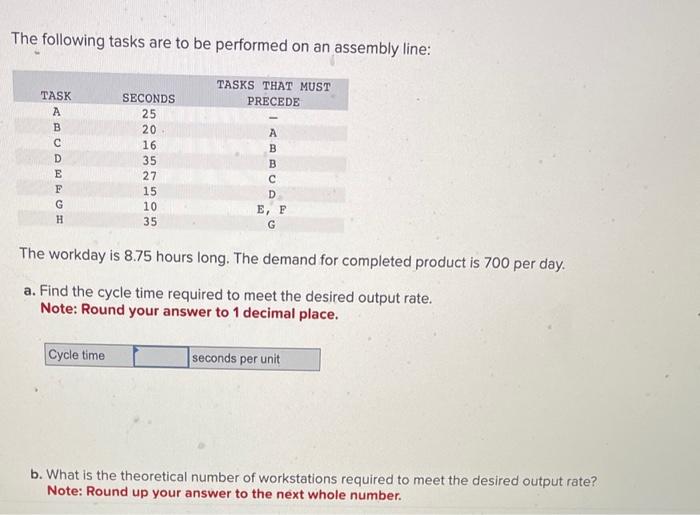

The following tasks are to be performed on an assembly line: *see image attached* The workday is 8.75 hours long. The demand for completed product is 700 per day.

a. Find the cycle time required to meet the desired output rate. Note: Round your answer to 1 decimal place.

b. What is the theoretical number of workstations required to meet the desired output rate? (Round answer to whole number)

c. Balance the line using sequential restrictions on the longest-operating-time rule. Determine the task under each workstation and the ideal time for each such task. NOTE: leave no sells blank. Be certain to enter zero whenever required round your answers to one decimal place

d. what is the efficiency of the line balanced as in part C assuming it is running at the cycle time determined in part a

e. suppose that demand rose from 700 to 1000 units per day. determine the cycle time. Use the solution obtained in part C

f. suppose that demand rose from 700 to 1100 units per day determine the cycle time. (Use the solution obtained in part C) NOTE: round answer for cycle time to nearest whole number

The following tasks are to be performed on an assembly line: The workday is \( 8.75 \) hours long. The demand for completed product is 700 per day. a. Find the cycle time required to meet the desired output rate. Note: Round your answer to 1 decimal place. b. What is the theoretical number of workstations required to meet the desired output rate? Note: Round up your answer to the next whole number.

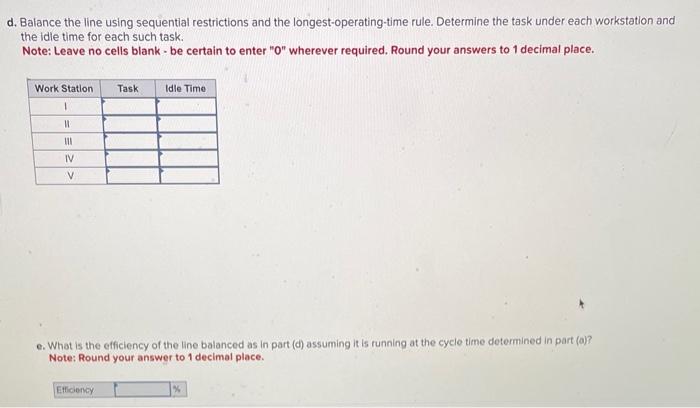

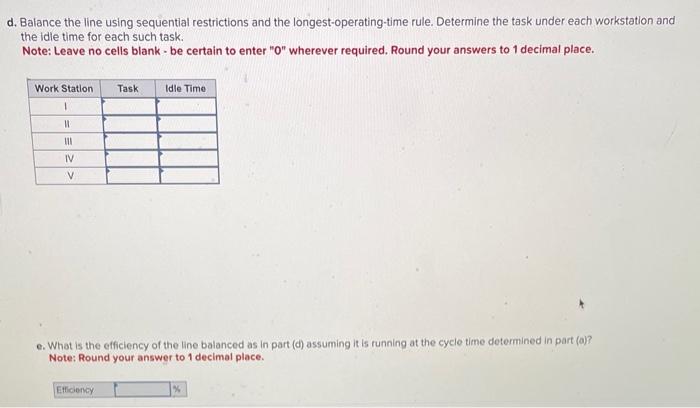

d. Balance the line using sequential restrictions and the longest-operating-time rule. Determine the task under each workstation and the idle time for each such task. Note: Leave no cells blank - be certain to enter "O" wherever required. Round your answers to 1 decimal place. e. What is the efficiency of the line balanced as in part (d) assuming it is running at the cycle time determined in part (a)? Note: Round your answer to 1 decimal place.

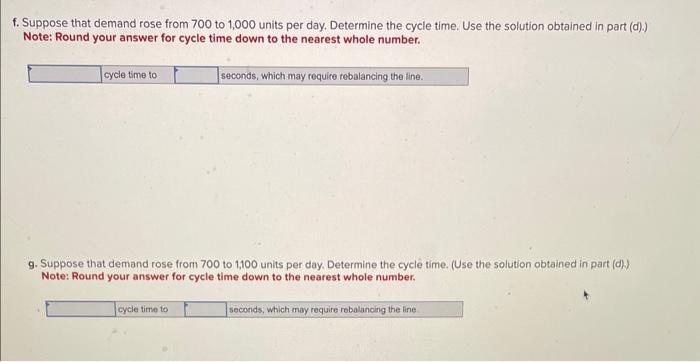

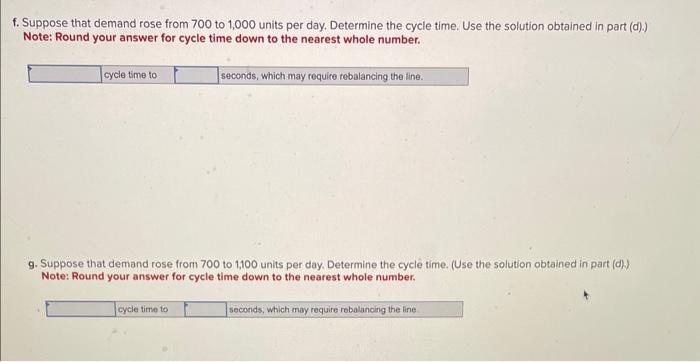

f. Suppose that demand rose from 700 to 1,000 units per day. Determine the cycle time. Use the solution obtained in part (d).) Note: Round your answer for cycle time down to the nearest whole number. g. Suppose that demand rose from 700 to 1,100 units per day. Determine the cycle time. (Use the solution obtained in part (d)) Note: Round your answer for cycle time down to the nearest whole number.