(Solved): Problem 1: Flowshop with Reentrant Machine-MILP vs Heuristic Context - Manufacturing Flow with Reent ...

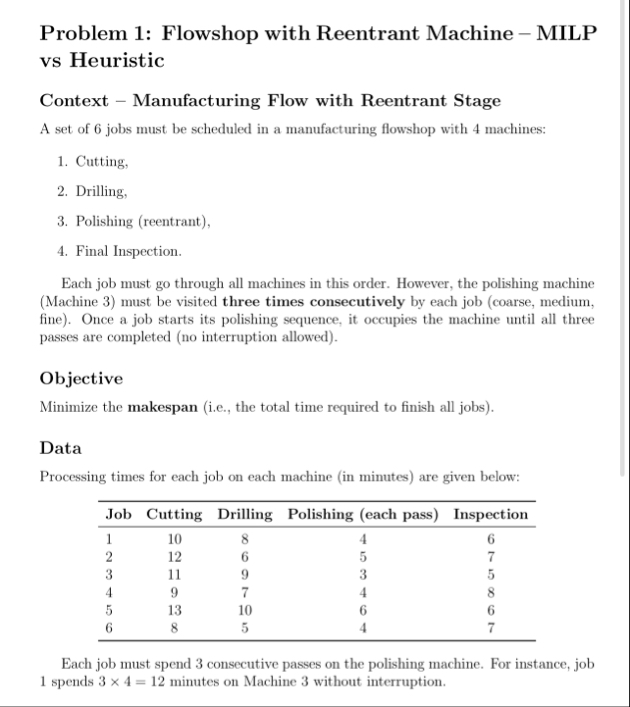

Problem 1: Flowshop with Reentrant Machine-MILP vs Heuristic Context - Manufacturing Flow with Reentrant Stage A set of 6 jobs must be scheduled in a manufacturing flowshop with 4 machines: Cutting, Drilling, Polishing (reentrant), Final Inspection. Each job must go through all machines in this order. However, the polishing machine (Machine 3) must be visited three times consecutively by each job (coarse, medium, fine). Once a job starts its polishing sequence, it occupies the machine until all three passes are completed (no interruption allowed). Objective Minimize the makespan (i.e., the total time required to finish all jobs). Data Processing times for each job on each machine (in minutes) are given below: \table[[Job,Cutting,Drilling,Polishing (each pass),Inspection],[1,10,8,4,6],[2,12,6,5,7],[3,11,9,3,5],[4,9,7,4,8],[5,13,10,6,6],[6,8,5,4,7]] Each job must spend 3 consecutive passes on the polishing machine. For instance, job 1 spends

3\times 4=12minutes on Machine 3 without interruption.Tasks Formulate a MILP model for this problem. Implement a heuristic (e.g., NEH-like rule or dispatching rule with polishing grouping). Compare both methods in terms of: Makespan, Computation time.