(Solved): The catalyst regeneration unit in an oil refinery is generating a flue gas containing air and dust p ...

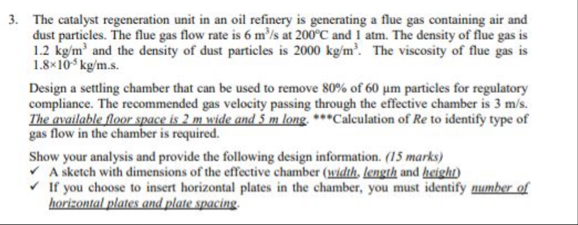

The catalyst regeneration unit in an oil refinery is generating a flue gas containing air and dust particles. The flue gas flow rate is

6(m^(3))/(s)at

200\deg Cand 1 atm . The density of flue gas is

1.2k(g)/(m^(3))and the density of dust particles is

2000k(g)/(m^(3)). The viscosity of flue gas is

1.8\times 10^(-5)k(g)/(m).s. Design a settling chamber that can be used to remove

80%of

60\mu mparticles for regulatory compliance. The recommended gas velocity passing through the effective chamber is

3(m)/(s). The available floor space is 2 m wide and 5 m long. ***Calculation of Re to identify type of gas flow in the chamber is required. Show your analysis and provide the following design information. (15 marks)

?A sketch with dimensions of the effective chamber (width, length and height)

?If you choose to insert horizontal plates in the chamber, you must identify mumber of horizontal plates and plate spacing.