Home /

Expert Answers /

Chemical Engineering /

the-mixture-of-acetic-acid-and-water-is-entering-a-multistage-countercurrent-extraction-system-the-pa664

(Solved): The mixture of acetic acid and water is entering a multistage countercurrent extraction system. The ...

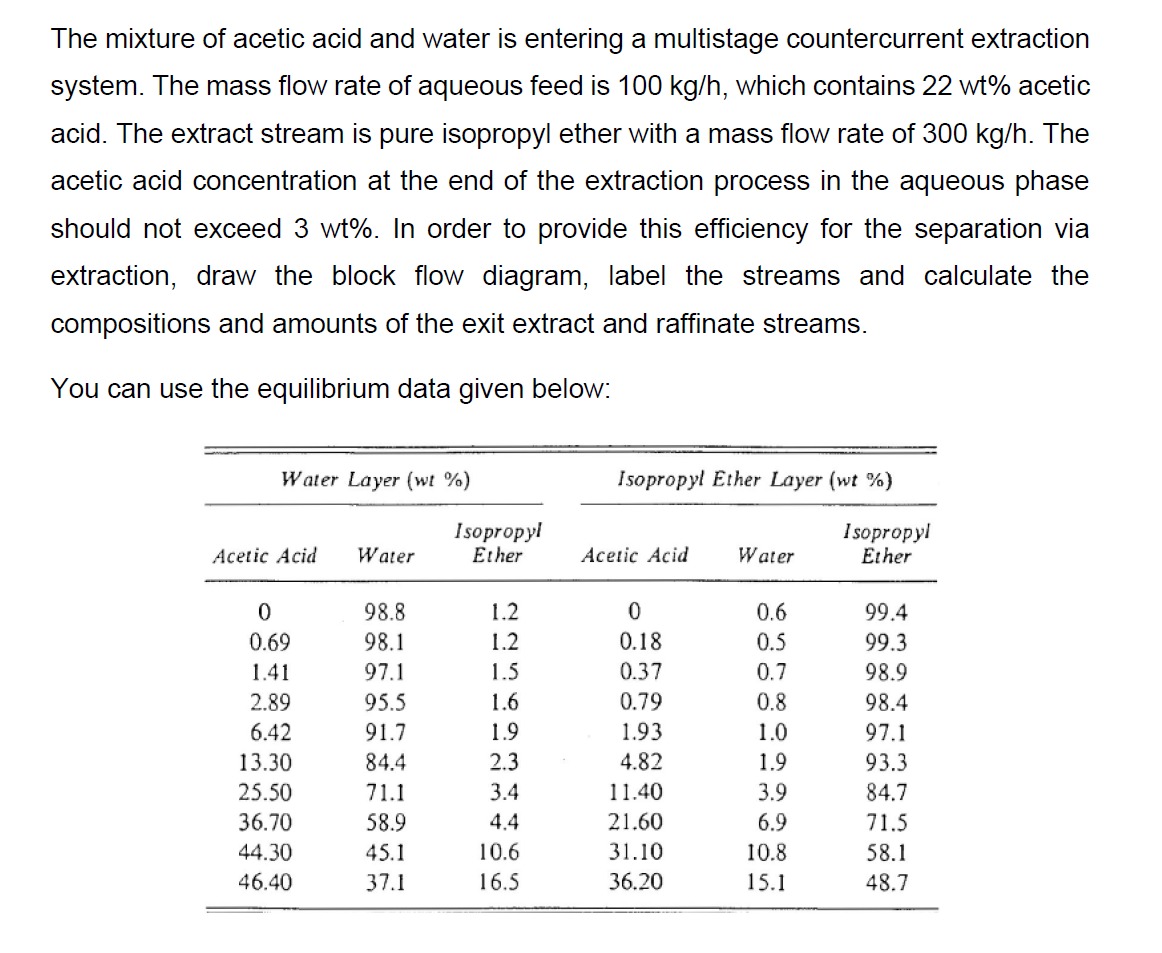

The mixture of acetic acid and water is entering a multistage countercurrent extraction system. The mass flow rate of aqueous feed is \( 100 \mathrm{~kg} / \mathrm{h} \), which contains \( 22 \mathrm{wt} \% \) acetic acid. The extract stream is pure isopropyl ether with a mass flow rate of \( 300 \mathrm{~kg} / \mathrm{h} \). The acetic acid concentration at the end of the extraction process in the aqueous phase should not exceed \( 3 \mathrm{wt} \% \). In order to provide this efficiency for the separation via extraction, draw the block flow diagram, label the streams and calculate the compositions and amounts of the exit extract and raffinate streams. You can use the equilibrium data given below:Isopropyl EtherIsopropyl Ether