(Solved): Use process selection charts for the following question. A pressure vessel is required for a hot-iso ...

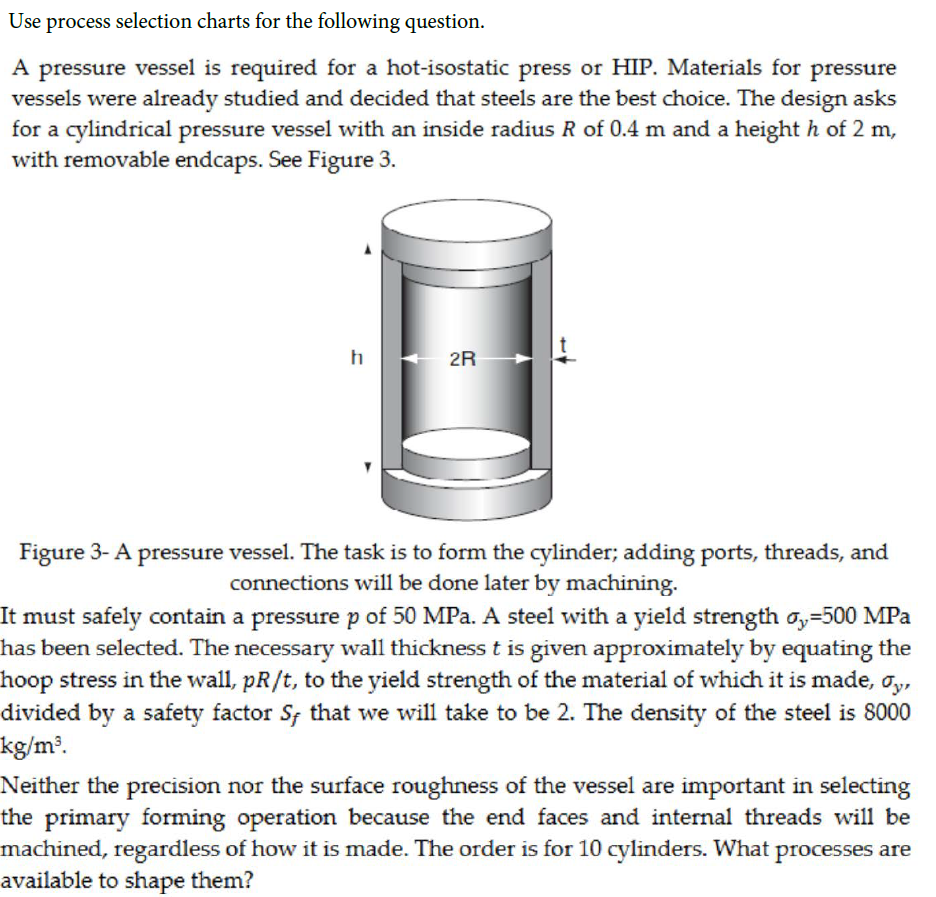

Use process selection charts for the following question. A pressure vessel is required for a hot-isostatic press or HIP. Materials for pressure vessels were already studied and decided that steels are the best choice. The design asks for a cylindrical pressure vessel with an inside radius \( R \) of 0.4 m and a height \( h \) of 2 m , with removable endcaps. See Figure 3. Figure 3- A pressure vessel. The task is to form the cylinder; adding ports, threads, and connections will be done later by machining. It must safely contain a pressure \( p \) of 50 MPa . A steel with a yield strength \( \sigma_{y}=500 \mathrm{MPa} \) has been selected. The necessary wall thickness \( t \) is given approximately by equating the hoop stress in the wall, \( p R / t \), to the yield strength of the material of which it is made, \( \sigma_{y} \), divided by a safety factor \( S_{f} \) that we will take to be 2 . The density of the steel is 8000 \( \mathrm{kg} / \mathrm{m}^{3} \). Neither the precision nor the surface roughness of the vessel are important in selecting the primary forming operation because the end faces and internal threads will be machined, regardless of how it is made. The order is for 10 cylinders. What processes are available to shape them?